research

2019.11

Structure & Texture

Experimenting with the structure and texture of the bacterial cellulose has been divided into three categories: Folding, Molding, Stiffening.

From the experiments, it turned out that plastic and glass are the best materials to mold the bacterial cellulose. Compared to coconut oil, using a layer of linen in the mold helped the material to come off much easier, enabling it to mold a very thin material. In addition, a structure can be created in the material during the brew. Bacterial cellulose grows in any kind of shape and form as long as it gets enough oxygen supply.

Wet bacterial cellulose holds the texture of the mold very well. Adding stiffness to the material is done by trapping bamboo sticks (or other materials) between two layers of bacterial cellulose. The sticks give the material more support, resulting in a sturdy yet flexible material.

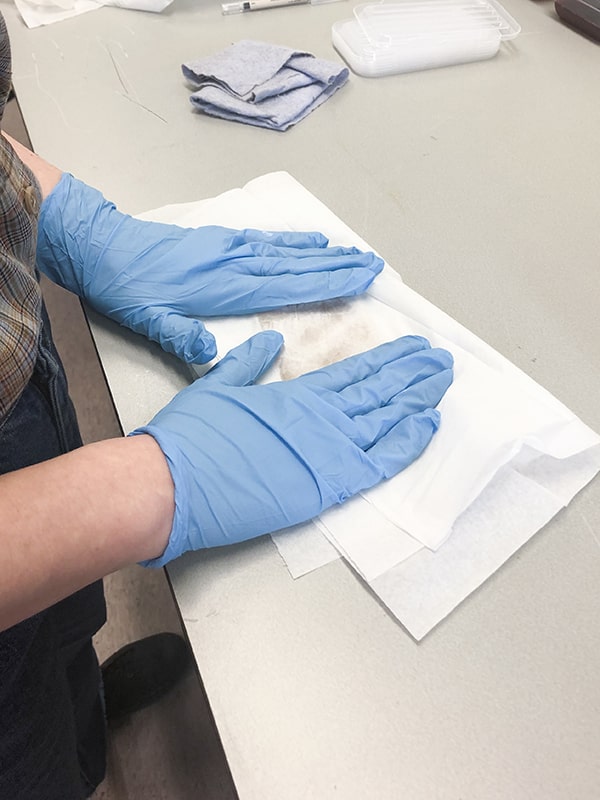

Folding:

As the treated sample has resulted in a paper like material, further experiments were carried out to explore the structural possibilities of the material. A piece of bacterial cellulose is pressed in between two layers of linen and is folded when dried. This sample resulted in a paper-like material with a flat and smooth surface. The texture of the linen was slightly visible. The material easily folds and is able to hold the fold as well as paper. When a wet treated bacterial cellulose was folded and pressed with linen, it resulted in a very sharp fold when compared to the sample folded after it’s dried. However, this sample did not have a smooth surface: more wrinkles are visible.

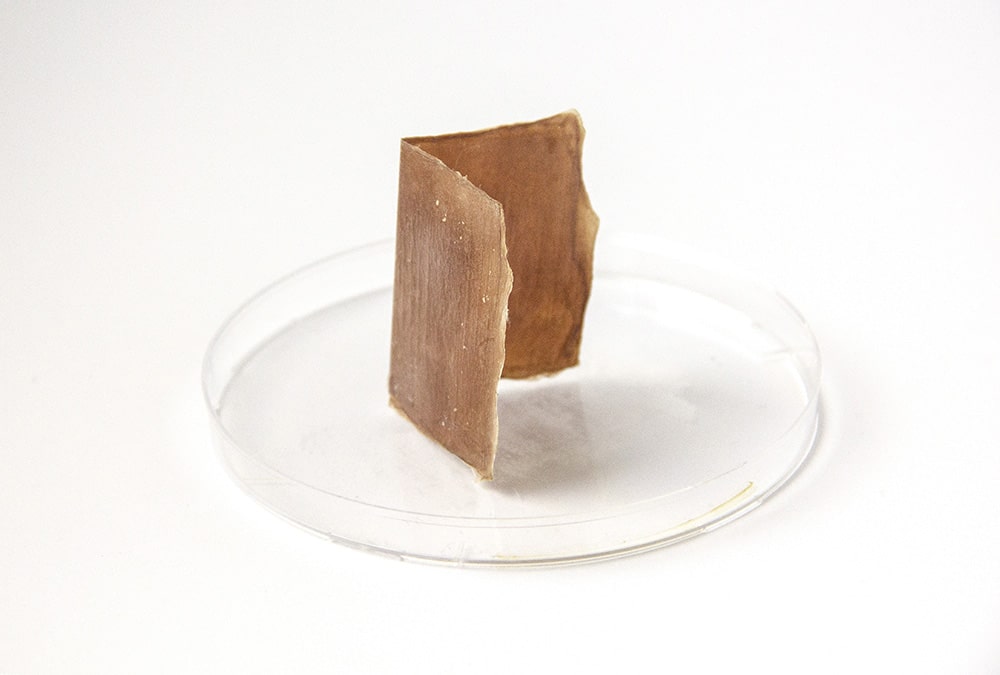

Molding:

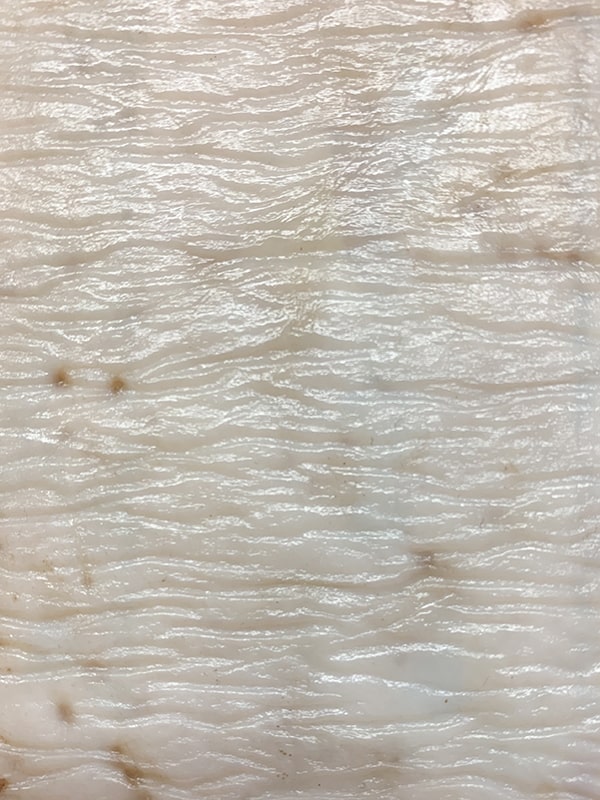

To adjust the material’s structure, some molded samples have been made using bacterial cellulose. In order to see which mold works best, different mold materials are used; silicon, plastic, glass, and ceramic. From the different mold materials used, plastic was the most effective as the material came off quite easily. The bacterial cellulose can be molded into various shapes and still hold its form. The molds were rubbed with coconut oil to make the material come off easier when it’s dried. As an alternative to coconut oil, an experiment using linen in between the material and the mold has been executed. The linen helped the material to come off a lot easier when compared to coconut oil. The use of linen provides the possibility to make a thinner layer, as it will not tear when it’s being pulled off the mold. A thinner layer of bacterial cellulose results in great transparency. The properties of the material are similar to plastic in terms of strength and structure.

Stiffening:

Adding stiffness to the material is done by trapping bamboo sticks (or other materials) between two layers of bacterial cellulose. The sticks give the material more support, resulting in a sturdy yet flexible material.